Spur® Double Stage Weatherproof Louvres

Overview

Spur® Double Stage Louvres are commonly selected for buildings that require greater levels of rain defence where plant and equipment areas require high levels of watertightness. Arcadia's range of tested performance Louvres are engineered and tested to AS 4740:2000 and provide engineers and designers a guaranteed performance result. There are a broad range of Louvre profiles available including drainable louvre systems to meet differing project requirements for pressure drop and rain defence. In addition this louvre range provides a high level of privacy and screening for mechanical plant and equipment.

Class 2 2 - CD = 0.5 to 0.699

Class 3 3 - CD = 0.3 to 0.499

Class 4 4 - CD = 0.1 to 0.299

Class B B - 0.989 to 0.95% Effectiveness

Class C C - 0.949 to 0.80% Effectiveness

Class D D - Below 0.80% Effectiveness

Class 2 2 - CD = 0.5 to 0.699

Class 3 3 - CD = 0.3 to 0.499

Class 4 4 - CD = 0.1 to 0.299

Class B B - 0.989 to 0.95% Effectiveness

Class C C - 0.949 to 0.80% Effectiveness

Class D D - Below 0.80% Effectiveness

Class 2 2 - CD = 0.5 to 0.699

Class 3 3 - CD = 0.3 to 0.499

Class 4 4 - CD = 0.1 to 0.299

Class B B - 0.989 to 0.95% Effectiveness

Class C C - 0.949 to 0.80% Effectiveness

Class D D - Below 0.80% Effectiveness

Features

Propelling High Performing Louvre Designs to Meet HVAC and Engineering Needs

Specifying weather louvres can be challenging, and if you don’t take into account all of the relevant considerations, you risk selecting the incorrect louvres for your project. Check out our whitepaper our educational whitepaper to help guide you draft an effective louvre specification.

Using a Testified and Certified Louvre System

The Australian Standard AS4740 sets out the requirements of testing of louvre systems. This testing is conducted in a testing rig and provides industries standards for airflow performance and rain defence. An untested and uncertified louvre system can result in poor airflow performance and impact on personnel wellbeing. The Spur® Fixed Louvre Systems have been exhaustively tested and certified using Australian Standards AS 4740.

Airflow Performance

Louvre airflow performance is affected by a range of physical elements including the louvre blade configuration, the louvre depth, the quantity of passes (single, double, triple stages), the louvre blade shape and any protrusions that interfere with the free flow of the air or that cause turbulence. Increased air velocity may cause varying areas of turbulence and flow disturbance which affect the louvre performance.

Weatherproof Louvres Protect Against Harsh Weather

Incorporating weatherproof louvres into a structure’s design protects structures from adverse weather conditions. This is an essential architectural feature designed to withstand various weather conditions. Arcadia’s louvres are specially engineered to prevent rain, snow, wind, and other elements from penetrating the building’s interior– all while allowing ventilation and air exchange within a building.

Stormproof Louvres Shield Against High Winds and Storms

Cyclones, tropical storms, and high winds are inevitable forces of nature that could destroy buildings and homes. Our stormproof louvres are designed to withstand severe weather storms and resist high wind pressures. Our louvres reduce the risk of wind-driven forces on buildings, decreasing the likelihood of damage to any structure. Integrating stormproof louvres into a structure’s design enhances resilience and ensures the safety of occupants during storms.

Factors to Consider When Choosing Weatherproof Louvres

Severity of local (site) weather conditions

Location and exposure of louvres on building

Airflow rate and direction through louvre

Maximum allowable water penetration

Maximum acceptable pressure drop

Relevant performance data (site requirements)

Special solutions for sloping applications and

Building Aesthetics

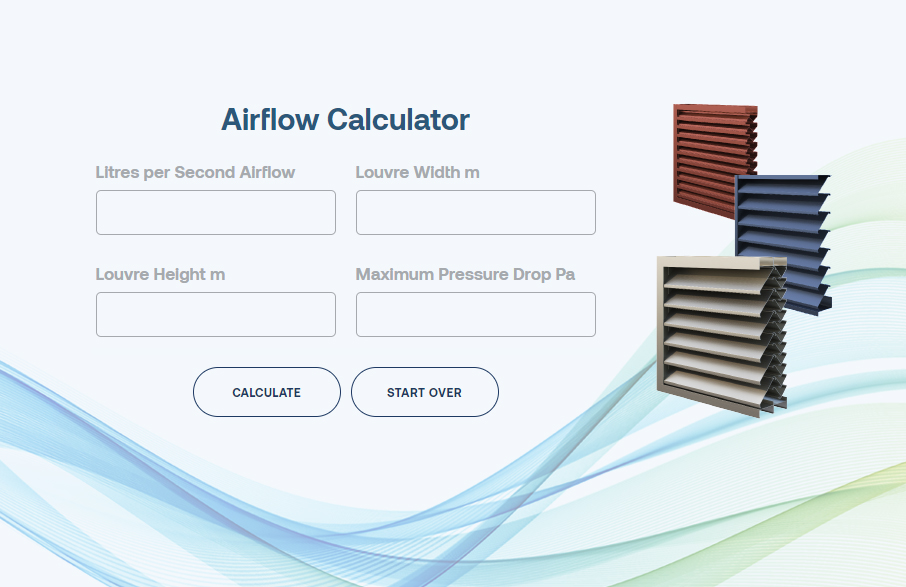

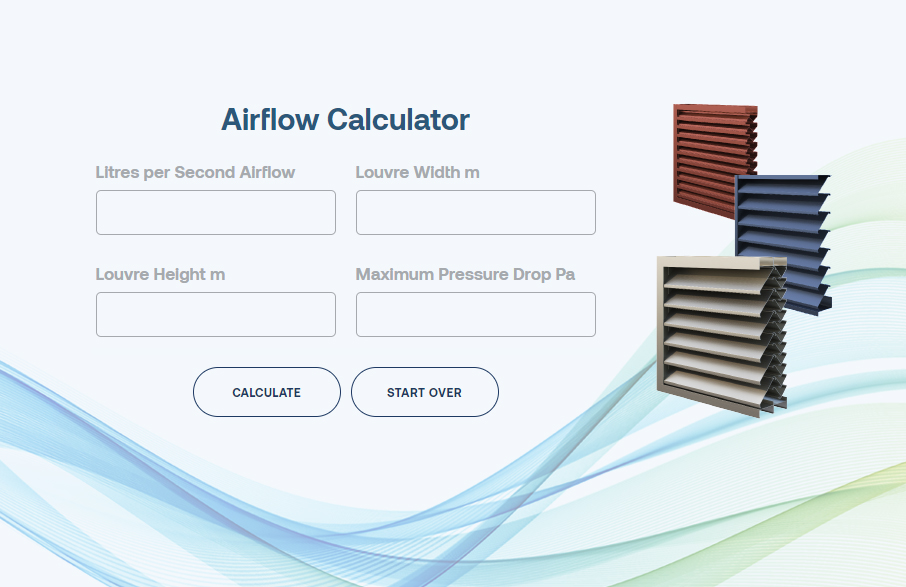

Louvre Performance Calculator

This user friendly calculator will help you choose the right louvres from our wide range.

LOUVRE CALCULATOR

Applications